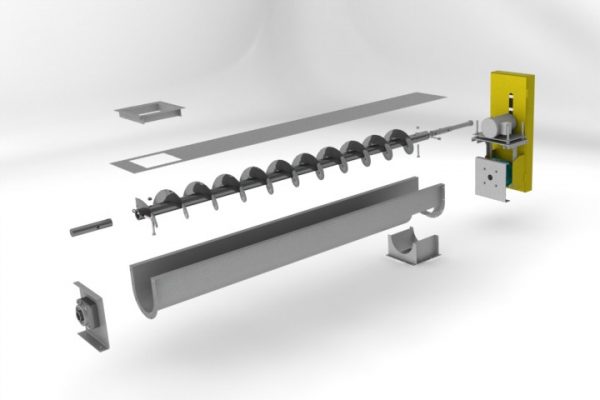

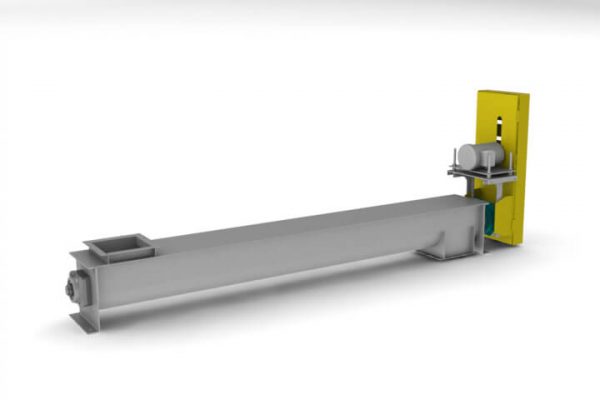

Archimedes had a great idea with his conception of the screw. Screw Conveyor Corporation took that concept and perfected screw conveyors that are easy to install, simple to maintain, and adapt easily to transporting bulk materials in a broad range of applications. Quality screw conveyor systems and parts are available in a wide range of designs and materials. We can meet your application needs in Helicoid and Sectional Flights or with adaptations including ribbon, special pitch or tapered. Various gauges of steel, stainless steel, hardened flight surfaces and other alloys are also available. Screw Conveyor Corporation carries a large inventory of standard parts and modular packages to resolve specific CEMA component failure or full system replacement. From CEMA Standard products to engineered material handling solutions – Screw Conveyor Corporation is ready to help you.

The Common-Sense Choice

Screw conveyors pose several benefits. They are capable of conveying dry to semi-fluid bulk materials, ranging from free-flowing to sluggish in regard to viscosity. Screw conveyors are also more economical alternatives to a belt, pneumatic, or aeromechanical conveying device. Using multiple inlets and discharge points, screw conveyors efficiently distribute bulk materials to different areas. Plus, screw conveyor systems are able to contain corrosive or hazardous materials.

Keeping Business Productivity Up

Having the right equipment helps your business reduce costs and maintain high-productivity. We have a vast assortment of options available to better ensure the right solution for you.

Serving the Americas

Screw Conveyor Corporation dedicates its time and efforts to serving the Americas. We have three locations throughout the United States serving North American markets, as well as our sister company, Screw Conveyor de Mexico, which serves the Central and South American markets. Our company engineers and manufactures various conveyance systems.

You can expect the best when you choose us for bulk handling equipment. Contact Screw Conveyor Corporation today to learn more about our screw conveyor systems and parts.

Screw Conveyor Capabilities

| Material must be control fed to the Screw Conveyor | |

| CEMA Standard Diameters | 6 – 24 in. |

| Non-CEMA Units | 30 in. and 36 in. |

| Typical Length Range | Up to 150 ft. |

| Incline | 0 – 45° |

| Typical Capacities | Up to 18,000 cu ft./hour |

Screw Feeder Capabilities

| Used to regulate material flow from a hopper or choke load condition | |

| Standard Diameters | 6 – 24 in. |

| Typical Length Range | 5 – 20 ft. |

| Incline | 0 – 15° |

| Typical Capacities | Up to 18,000 cu ft./hour |